SLIMLINE

SLIMLINE

The modular “Slimline” concept is leading the way, especially for its novel design, which has a much higher level of pre-assembly in the workshops compared to a standard incinerator design.

Since its inception, the company has been striving to be at the forefront of technological innovation. It was one of the first to propose the concept of “mobile waste inceneration plant”, offering an important factor of flexibility to those entities in need of small, mobile plants for managing waste in diverse and remote locations.

Building on this concept, Hafner today offers also modern stationary thermal waste incineration plants with energy recovery in a modular design and turnkey plant technology called H® - SLIMLINE.

H® - SLIMLINE means the following:

The new plant concept "Slimline" from Hafner means the following advantages and possibilities:

- Solution to waste problems even for smaller environments (Up to 25,000 t/year).

- Expandable to 4 additional Waste to Energy lines, each capable of taking on 25,000 tons of waste per year;

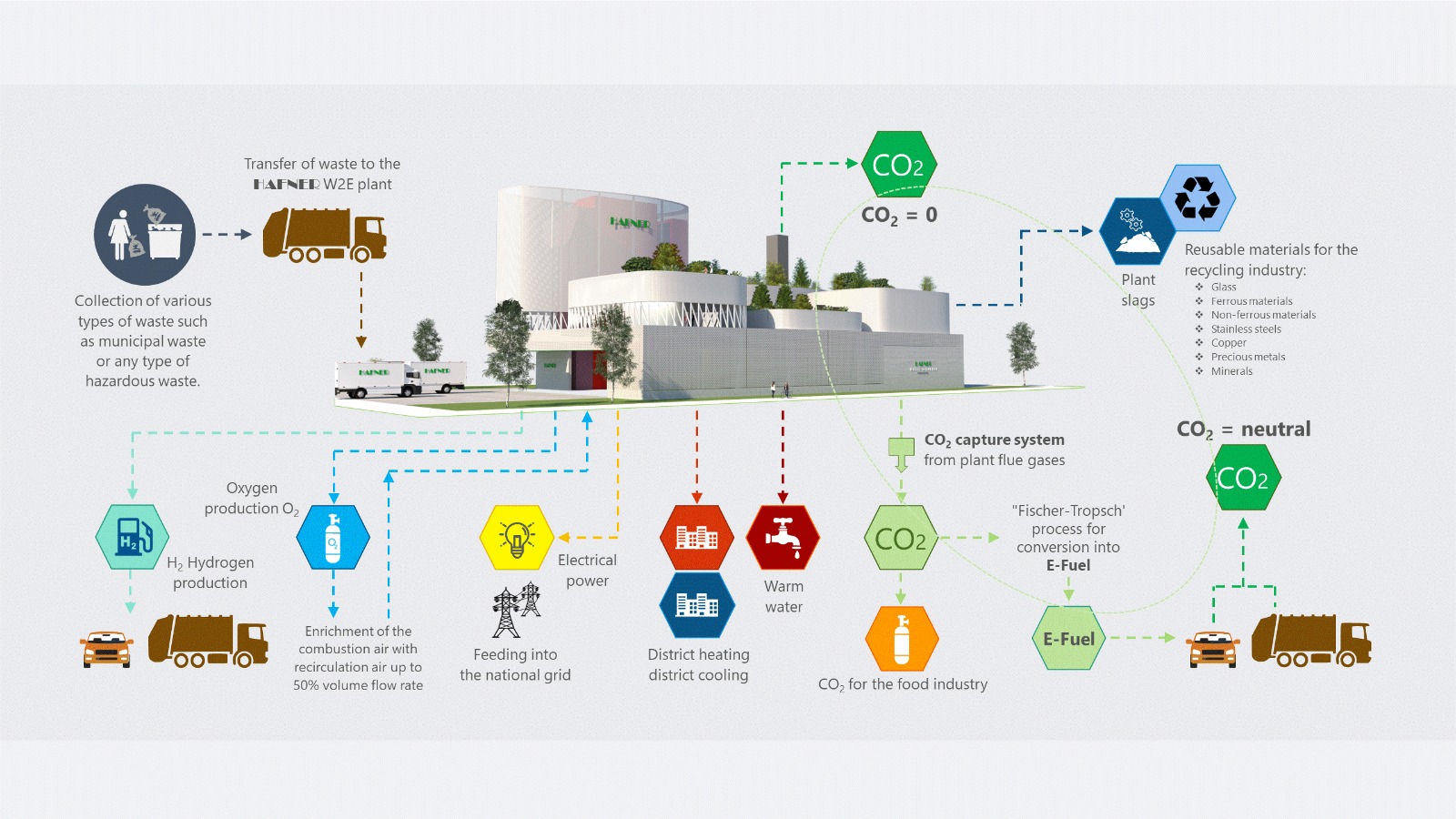

- Energy from Waste: Energy (electricity, cooling, district heating) from household or hazardous waste;

- Fast assembly on-site thanks to the well-designed modular block structure system;

- Less space required for installation compared to conventional inceneration plants or W2E plants;

- The lowest flue gas emissions in Europe;

- Fixed price guarantee - from the beginning guaranteed;

- Clearly defined construction times and fixed date for commissioning;

- Re-introduced CO2 technologies

Module Concept of a Typical H® - SLIMLINE:

Hafner's well-functioning logistical organization is an advantage as all the parts required for assembly must arrive at the construction site almost together.

Using the dust filter as an example, only the bag filters with the stainless-steel baskets have to be inserted in a second moment and the dust discharge has to be mounted.

Another example of a modular design is the reactor, which is delivered on site in a single prefabricated part and can be mounted by one train.

Other plant components which consist of a single prefabricated main part are among others the cyclone, chimney, the ID-fan and all smaller plant components such as compressors and ventilators which are delivered as ready installed equipment with a modular container version.

The containers are standard shipping containers of 20´ or 40´, which are rebuilt inside to fix the various plant components.

A Typical Facility:

The turn-key H® - SLIMLINE includes engineering, construction, manufacturing, assembly, commissioning and the training.

A facility shall include following processes:

- Waste feeding system

- Storage and transportation systems for consumption materials

- Thermal incineration process, (grate type furnace)

- Waste heat boiler (water-steam cycle) integrated post combustion zone;

- Dry gas cleaning system

- One Turbine generator unit

- One Condensate system

- Electrical facilities

- Instrumentation and controls and communication infrastructure

Address

Via Giuseppe Di Vittorio 16

Bozen/South Tirol,

39100 - ITALY

Call Us

Phone: +39 0471 566 300

Business Dev.: +39 0471 566 331

Email Us

Secretary: info@hafner.it

Business Dev.: office@hafner.it